Showing 1–16 of 52 results

Main features

- One of its kind precision during cutting of complicated shapes

- Range from 1-150 mm material thickness

- EtherCAT® technological solution that ensures reliable connection of machine components

- Various safety packages available

- Power LED lighting for more safety at work

- Integrated modules inside of the machine provide better resistance for adverse influences from cutting process

Main features

- highly dynamic 2D precision cutting of sheets and profiles

- capability of processing plates from 0,5 mm to 100 mm thickness

- expanded base of predefined cutting parameters

- unlimited possibility of increasing the length of the working area

- individual customizing options

Main features

- plasma Vortex 3D FL head ensure the best precision of automatic 3D cutting of plates, tubes and profiles

- more bridge rigid make possible to cut 1-300 mm thickness plates,

- modern i-Vision controller installed on moving arm delivers the unique ergonomic and comfortable work,

- modified drive system ensures clear X axle positioning during dynamic cutting,

- Power LED lighting and light curtains warrants safe work,

- perfect scores thanks of greater base of predefined plasma and oxygen cutting parameters,

- integrated modules inside of the machine make better resistance for adverse influences from cutting process,

- Onyx has Hypertherm® True Hole™ certificate and Kjellberg® Contour Cut™ technology.

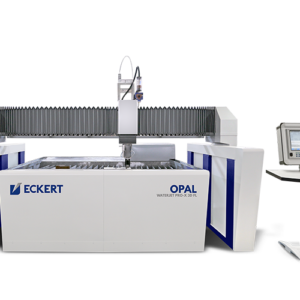

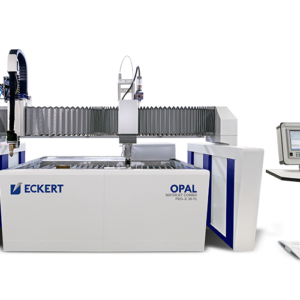

Main Features

- versatility

- there are no dust as a by-product of cutting

- abrasive or pure water cutting

- waterjet cutting system can operate with up to four cutting heads at a time

- customised high pressure pump adjustment

- dross free cutting minimizes post processing

Main Features

- innovative, patent protected technology of integrating waterjet and plasma allows automatic cutting utilizing both of them

- fully automated cutting process with two different cutting technologies

- the reduction of production costs even by 70% with comparison to standard waterjet machines

- universal cutting tool for every material

- possibility of installing Pro-X 3D head

- ability to apply any required technology during edge cutting of a single element

- robust construction and reliability

- Cutting capacity of steel up to 30 mm thickness

- Use of an ecological water table to reduce noise and pollution

- High durability thanks to the independent construction of the bridge and working table

- High class equipment from prestigious suppliers

- Unmatched ease of use

Main features

- highly dynamic and precise in automated 2D/3D cutting of sheets, tubes, beams

- capability of processing plates up to 200 mm thickness

- expanded base of predefined cutting parameters

- unlimited possibility of increasing the length of the working area