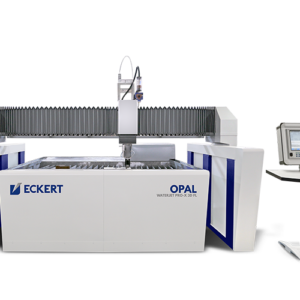

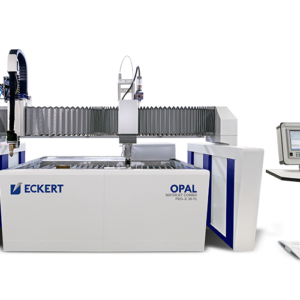

ECKERT CHROME

Main features

- One of its kind precision during cutting of complicated shapes

- Range from 1-150 mm material thickness

- EtherCAT® technological solution that ensures reliable connection of machine components

- Various safety packages available

- Power LED lighting for more safety at work

- Integrated modules inside of the machine provide better resistance for adverse influences from cutting process